What is PAS2080?

The full name is PAS2080:2023 Carbon Management in buildings and infrastructure, which gives a good basic idea. It is a ‘Publicly Available Specification’ that defines good practice standards for the carbon management process. It is globally recognised and authored by the Construction Leadership Council, the Green Construction Board, the ICE and BSI, for the management of carbon in construction projects.

What is carbon management?

Carbon management is similar to financial management but instead of £, $, and € the currency is tCO2e which translates as tonnes of carbon dioxide equivalent. A standard ‘equivalent’ unit is required as there are a number of greenhouse gasses attributed to global warming with different ‘global warming potentials’ (carbon dioxide, methane, nitrous oxides etc). To make the effect of all these gasses comparable they are converted to the amount of warming that is caused per unit of CO2. The CO2e emissions may be released from a range of sources including burning fossil fuels, decomposing biological material, land use change, melting permafrost, and drying out and erosion of soils.

Now that the currency is sorted there is also a budget, and this is set at different levels. There is a global carbon budget for limiting global warming to 1.5°C and likewise for 2.0°C, unfortunately we have nearly already used up all the budget for achieving 1.5°C. There are also national carbon budgets to meet national targets. Most countries and even local authorities have “Net Zero” targets where they aim to be carbon neutral by a given year such as 2050. We can then set carbon reduction targets on projects that align with the Net Zero ambitions of the Client and wider project team. Carbon management is thus the methodology of how we can limit our “spending” of carbon to achieve these targets. Much like financial management the more detail you get into the more complicated it can get, and questions of where to invest your carbon and where is best to cut carbon are multifaceted and complex questions that often contradict other sustainability ambitions or project constraints. One important difference with the financial comparison however is the overall goal is always to reduce the carbon budget and reduce the amount of carbon emitted or spent. Unlike finance where the general aim is the never-ending growth of profit and financial capital.

How does PAS2080 work?

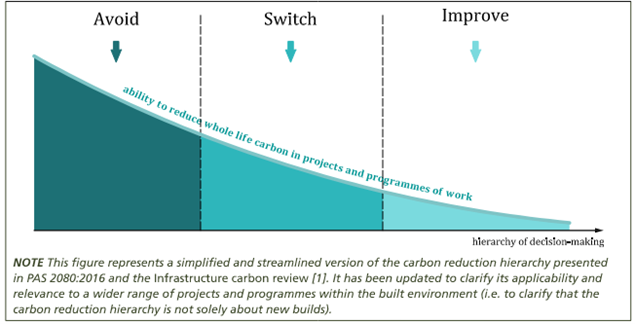

What PAS2080 does is provide a framework and process around managing projects and their use of carbon. It is not prescriptive to specific engineering disciplines and does not dictate any calculation methods. It does however provide a base, a foundation perhaps… which practitioners can build upon, to develop their discipline specific engineering solutions that use the least amount of carbon. It does not tell you what to build, but more that reducing carbon should be built into the decision-making process. For example Figure 1 shows how we can achieve greater carbon savings by Switching than Improving and yet more by Avoiding hence the Hierarchy of decision making advised is always to try Avoiding first then Switching then Improving.

Figure 1 – Carbon reduction Hierarchy. Taken from PAS2080: 2023

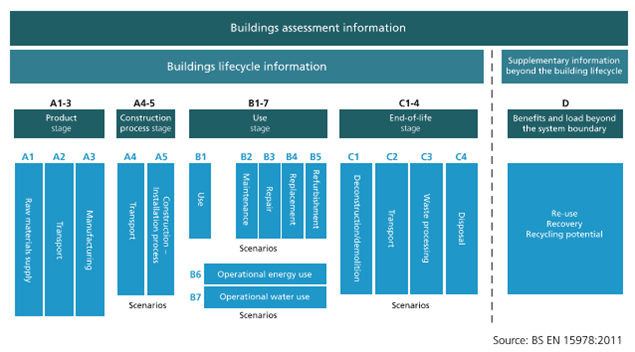

PAS2080 applies to and links all value chain members from asset owners and managers, designers and constructors to product/material suppliers. Each value chain member and practitioner has different responsibilities, however there are overlapping requirements that cut through all roles. The general process consists of quantifying the estimated embodied carbon (the tCO2e spent through the production of materials, their transport to site, and onsite activities) of the project in a baseline assessment. Then setting targets to reduce this and undertaking iterative assessments as the design develops looking to continually improve the carbon reductions. A core principle of the PAS, is working collaboratively to reduce carbon across the value chain and reporting on the results. A key part of the assessment and quantification of embodied carbon is undertaking lifecycle assessments that incorporates the BS EN 15978:2011 standard which distinguishes between construction stage (A1 – A5), use stage (B1 – B7) and end of life stage (C1 – C4) emissions.

Updates from PAS2080:2018 version include a more integrated approach to the wider built environment realising that the most effective solutions require systems thinking to be fully successful. For example by using nature-based solutions that have multiple benefits across multiple different systems, such as improved drainage leading to greater resilience to flooding and climate change, as well as increased local biodiversity helping to restore nature and improve the wellbeing of local people.

A further update is that the Whole Life Carbon of an asset is considered, so that we can quantify and manage the carbon required to build, maintain, use, and then finally manage the end of life of the asset.

How does PAS2080 apply to Ground Engineering?

Ground Engineering is not isolated from PAS2080 and can make a huge contribution to managing carbon on projects. We ‘spend carbon just like any other discipline, every tonne of concrete and steel in foundations costs carbon in their production, transportation, and installation. Every tonne of soil excavated and transported spends carbon in the plant/ truck emissions. PAS2080 provides the framework for how we can reduce this carbon expenditure.

PAS2080 does not say what solutions geotechnical engineers should use, but it does explain the general principles that geotechnical engineers should follow to reduce carbon. For example,

accurate accounting for the carbon used across the whole life cycle, following the carbon reduction hierarchy (avoid-switch-improve), using nature-based solutions. It is up to us as engineers to apply this framework to Ground Engineering and apply the solutions that comply.

The application of PAS2080 in a Ground Engineering context could look like the following. A baseline carbon assessment is undertaken that includes the substructure for a proposed development; this will be based on early assumptions such as that the development is a 5-storey building including a 1-storey basement on weak clay in a brownfield site, so we are probably going to need piles of Xm length. A hot spot analysis of the baseline assessment could find that the concrete and rebar used in the piles is where the biggest geotechnical associated carbon costs are. The responsibility of the geotechnical team is to find ways to reduce the carbon of the substructure solution. Applying the carbon reduction hierarchy, we look to build nothing first, so can we reuse existing foundations and utilise performance based design methods such as the observational method for the existing basement retaining walls to try and avoid spending carbon on additional structural elements by utilising increased monitoring, and hence enabling a leaner design? If not, can we switch to an alternative design that uses less carbon such as shallow foundations and ground improvement? If this isn’t an option, can we look to improve our design by doing additional soil testing and pile testing so we can reduce the size or lengths of the piles? Finally, can we look at replacing the materials to lower carbon, reusable, alternatives such as low carbon concrete and recycled steel. Further improvements can be found by reducing waste by utilising DfMA (Design for Manufacture and Assembly). The carbon savings of each of these changes will be quantified throughout the design process.

Collaboration is also vital throughout the process, designers and contractors need to speak to concrete suppliers to understand what mixes are available. Geotechnical Engineers need to speak with the structural engineers to understand if layout changes can help reduce the loading on the piles, hence reducing the required capacity and pile length. These changes and solutions are all common concepts in our sector primarily as ways to save money, but they also save carbon. The final solution will take into account other factors such as cost, programme, constructability etc. but often cheaper in cost equates to cheaper in carbon and PAS2080 helps to quantify and highlight this fact. By applying PAS2080 we can observe how the biggest carbon and cost savings can be made earlier on in a project which is why the process needs to start at the very beginning.

PAS2080 provides a project management level framework and process that is going to be increasingly used in construction, facilitating the reduction of carbon and achieving Net Zero. Companies will need to be PAS2080 certified to act as a Tier 1 contractor on National Highways projects from 2025. This is a sign of things to come with carbon reduction increasingly becoming a part of contract requirements and performance specifications. As crucial members of project teams, geotechnical engineers will be contributing to this either directly or indirectly. Having a basic understanding of PAS2080 will help geotechnical engineers collaborate with their colleagues on the wider project team. We will also be contributing directly by developing and implementing designs to make the actual carbon reductions following the principles in PAS2080. Much of the geotechnical engineer’s role will be business as usual with carbon reduction just another factor to consider. We do however have great potential to contribute to the reduction of carbon emissions in the construction sector, and we should be continually looking to push the envelope of what is possible and come up with innovative, boundary pushing designs in the name of sustainability and carbon reduction. Advocating the use of new and innovation products, and perhaps taking inspiration from the 2023 Geotechnique lecture (Accessible here: https://www.ice.org.uk/events/past-events-and-recordings/recorded-lectures/vegetation-solutions-into-geotechnical-engineering-design) and bring vegetation-based solutions into geotechnical engineering design.

Call to action

We have been given a new framework to follow, but the role of engineers, including geotechnical engineers remains the same. We need to solve problems and design the best possible solutions. It’s just now the problem includes climate break-down and the best solutions are the ones with the lowest Whole Life Carbon.

Figure 2: Lifecycle stages of building works assessment. Taken from the ICE PAS2080 guidance document.

References

2023. BSI. PAS2080:2023 Carbon Management in Buildings and Infrastructure

2023. Construction Leadership Council, The Green Construction Board. Guidance Document for PAS 2080.

2023. ICE. Guidance Document for PAS 2080.

Article provided by Michael Trubshaw (Ramboll)