State of play

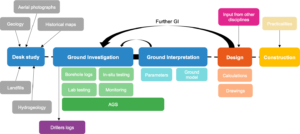

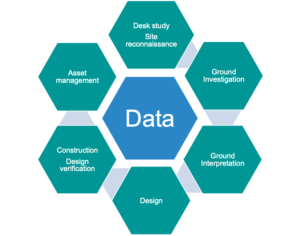

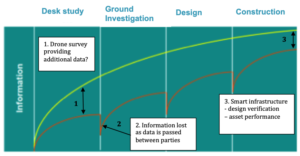

Figure 1 – Overview of the Engineering Geology Life Cycle and data collected throughout

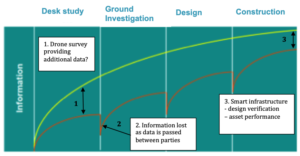

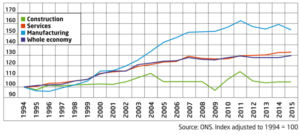

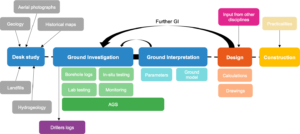

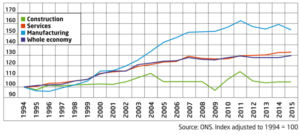

As it stands the engineering geology life cycle (Figure 1) feels a bit disconnected, especially when it comes to passing data through each phase of the project. This leads to data being lost at each stage of the cycle and ultimately the project never benefiting from all the potential information available (Figure 2). This is somewhat understandable given the number of different parties involved in the collection, processing and interpretation of data and each party focused on different phases of the life cycle. However, this should not be used as an excuse. The lack of technological advancements across the construction industry has also left us lagging behind other sectors of the economy (Figure 3).

Figure 2 – Schematic of the current and potential journey of information through the different phases of a typical engineering geology project

Figure 3 – Productivity of the construction industry compared with services, manufacturing and the whole economy.

Source: Taken from McKinsey Global Institute (2017)

The creation of the AGS data format in 1991 was a significant step to improving data transfer in the ground engineering industry. However, there have been limited further strides forward since then and we are approaching the 30-year anniversary since its introduction. So, what is the solution?

Data at the centre

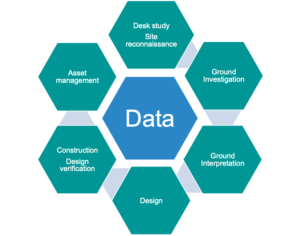

Figure 4 – The engineering life cycle with data at the centre

Firstly, we must put data at the centre of the engineering geology life cycle (Figure 4) and map out how data will move through the life cycle and the supply chain. By doing this we ensure data is transferred in the most efficient way possible. This must happen right at the start of the project.

The emergence of the Common Data Environment (CDE) facilitates this. The CDE is not new but its application is still limited to a select number of projects, despite the obvious benefits. For one, it provides a single source of truth that all parties can trust in. This is essential for large infrastructure projects such as HS2, Heathrow and Thames Tideway that have tens of thousands of documents across multiple disciplines. A CDE combined with a clear workflow also encourages collaboration and early sharing of information allowing engineering geologists and designers to make more informed decisions earlier in the project life cycle. For this to work we must also ensure there is interoperability between software and a well-defined data taxonomy is agreed across the industry (i.e. an AGS approach across the whole life cycle).

Where can technology assist?

It is important that any new technology has a clear tangible benefit. This might be increasing the accuracy of analysis, providing new data, improving efficiency of a task, facilitating better communication between the supply chain or improving safety. By identifying this ‘added value’ at the start of the project and reviewing it throughout ensures that technology is not used just for the sake of using it – something that potentially risks undermining the technology that will assist.

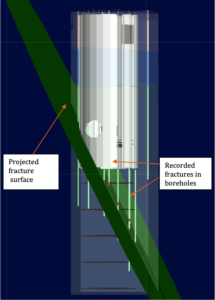

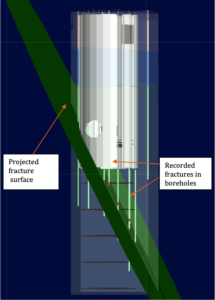

Figure 5 – Snapshot of Leapfrog model of Thames Tideway East shaft created to help visualize how potential fractures intersect with the shaft

Technologies that are already showing ‘added value’ include:

- Drones – Benefits include surveying large areas quickly, accessing places that are too dangerous for humans to access and ability to generate ‘intelligent’ 3D models of sites that open the door to ‘unlimited’ site visits;

- 3D Ground Modelling – Allows better visualisation of ground related risks to help ground engineers make more informed decisions. It also acts as a powerful communication tool to communicate ground risks to clients and other stakeholders (Figure 5); and

- Smart Infrastructure – Enables real-time asset data to be obtained that can assist design verification, early identification of potential problems and a predictive maintenance approach.

Artificial intelligence (AI) also has huge potential to assist the ground engineering industry. Yes, the ground is notoriously unpredictable making it difficult for AI to make reliable predictions on ground conditions or parameters. But based on historic data, AI could produce generative models that ground engineers could test and revise following targeted ground investigations.

Challenges

We should not shy away from the fact that embracing technology will bring its own challenges.

Four of the key challenges are:

- Upskilling of the industry;

- Validation of new software;

- Industry standards; and

- Industry culture.

Firstly, we must ensure that people are adequately trained in any new software tools and processes that are available (e.g. borehole logging using tablets). This is no easy task and ignites the debate as to whether the training responsibility lies with the industry or university. What is for sure though is that without the necessary skills to use and interpret the results from new technology we won’t be able to achieve nearly as much as we could. Geologists must also not forget their core skills of critical thinking and interpreting the subsurface.

Secondly, we must ensure new technology is robust and can be trusted. It is very easy to produce an all singing and dancing 3D model, but it must also make geological sense. Professor Fookes hinted at this in the First Glossop Lecture where he stated, “Technical innovation must stand the test of time in order to prove its worth”. We must also ensure that new processes and technology are also incorporated into existing industry standards or if required new standards developed.

The most difficult challenge of all, is the cultural transformation of the industry. Currently the value of data is not well enough understood, particularly among clients. As it is the clients who hold the purse strings, it is them who can lead the transformation. But it is equally the job of designers and contractors to share success stories and highlight the benefits that technology and effective information management can bring. This is particularly important if benefits are not realised until further down the asset life cycle. It is also crucial that the whole supply chain is singing off the same hymn sheet.

Where do we go from here?

Whether it is providing additional tools to better equip the ground engineer or creating cost savings for the client, the benefits of embracing new technologies and effective information management are clear. What we must do is to be better at sharing these benefits and success stories, particularly with clients.

Yes, there will be challenges along the way, particularly winning the hearts and minds of everyone in the industry but these are worth overcoming. We must remember that new technologies should make the life of an engineering geologist easier, not harder and allow us to focus on what we do best – critical thinking and interpreting the ground. It is important that these core skills are not sacrificed as these are things that technology cannot replace.

Article provided by Jonny Neville, Information Manager & Engineering Geologist at Mott MacDonald

Acknowledgements

- Costain, Vinci, Bachy (CVB) JV for allowing the inclusion of a snapshot of a Thames Tideway East shaft Leapfrog model.

Further reading

BIM model-based design delivery: Tideway East, England, UK. In Schooling, J. and Soga, K. (ed) Proceedings of the Institution of Civil Engineers – Smart Infrastructure and Construction, ICE Publishing, 170(3), 50-58.

Bolton, A., Butler, L., Dabson, I., Enzer, M., Evans, M., Fenemore, T., Harradence, F., et al. (2018). Gemini Principles. (CDBB_REP_006)https://doi.org/10.17863/CAM.32260.

Gakis, A., Cabrero, P., Entwisle, D. and Kessler, H. 3D geological model of the completed Farringdon underground railway station. In: Black, M, Dodge, C and Lawrence, U. (ed) Crossrail Project: Infrastructure design and construction, ICE Publishing, London, 632pp.

Network Rail. 2018. Earthworks Technical Strategy, 67pp.

McKinsey Global Institute. Reininventing Construction: A Route to Higher Productivity. February 2017.

Schwab, K. and Davis, N. Shaping the Fourth Industrial Revolution. World Economic Forum. 289pp.

Farmer, M. 2016. The Farmer Review of the UK Construction Labour Model.

Construction Leadership Council (CLC). 76pp.